What we do

Our offering

Soundcoat specialises in tailored acoustic insulation solutions for equipment used in various sectors. For over six decades, it has been building sound relationships with manufacturers and developing pioneering noise solutions, propelled by a spirit of innovation that enables it to tackle market challenges head-on.

Renowned for its products and customer-centric ethos, Soundcoat engages in close collaboration with clients from the initial stages of the equipment concept through to implementation and operation. Based in the US, it has operating facilities in New York and California.

|

PORTFOLIO HIGHLIGHTS

Soundcoat's highly-specialised engineering services are at the forefront of acoustics innovation and are led by an experienced team of acoustical engineers, incorporating industry-leading best practices; advanced computer simulation and predictive analysis; and proprietary Soundcoat techniques.

Our holistic approach yields customised solutions utilising a range of products tailored to specific needs:

|

Addressable markets

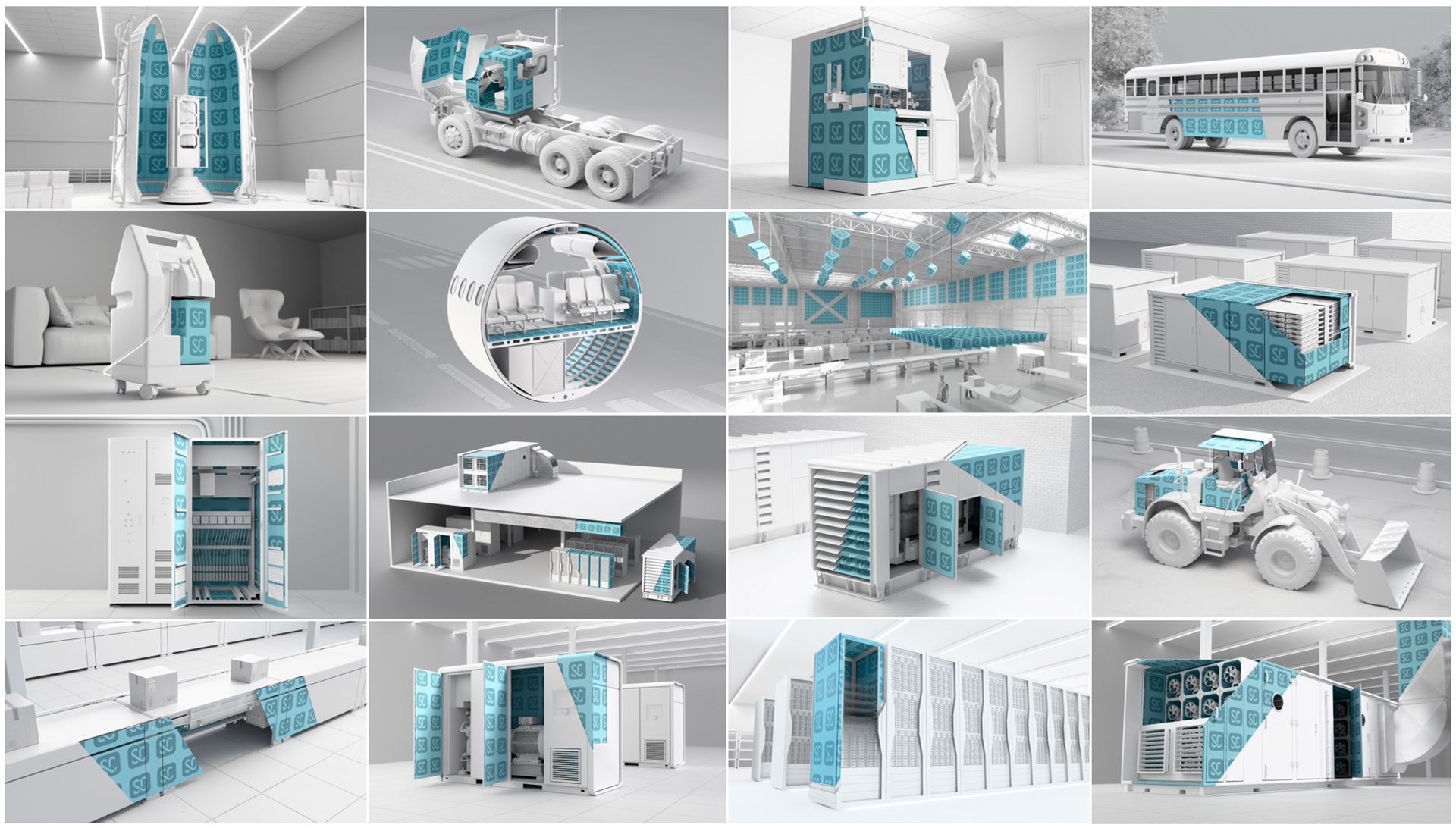

Soundcoat offers acoustic engineering services and product solutions to Original Equipment Manufacturers (OEMs) across various segments, including aviation, aerospace, heavy-duty and transport vehicles, energy storage and charging, generator sets, semiconductor processing equipment and medical equipment. These sectors are characterised by rapid technological advancements and increasing regulatory demands regarding sound level performance associated with the customer’s product.

Soundcoat serves the following markets:

- Aerospace & Aviation

- On-road heavy-duty vehicles

- Industrial equipment

- Building & Infrastructure

- Energy & Utilities

- Medical Equipment Manufacturing

- Electrical & Electronics

While remaining committed to its traditional industries, Soundcoat continues to push boundaries by expanding its activities in new and emerging sectors that will be critical to future growth. These include space exploration, electric vertical take-off and landing (eVTOL) aircraft, semiconductor manufacturing and electric vehicle (EV) charging infrastructure. By increasing our strategic focus on these sectors, we are aligning ourselves clearly with industries at the forefront of technological innovation. Our commitment to innovation and advanced solutions also aligns perfectly with Recticel Group’s overall vision for growth, innovation and excellence across all sectors.

Value of our thermo-acoustic insulation

Noise control is one of the great differentiators in equipment manufacturing. It sets the tone for product quality and can be integral to a brand’s reputation. Soundcoat maximises the value of its noise control solutions by approaching each project as a partnership. Its engineers collaborate with manufacturers on their designs and provide highly specialised subject-matter expertise and practical know-how throughout the design, manufacturing, testing, implementation and operational stages.

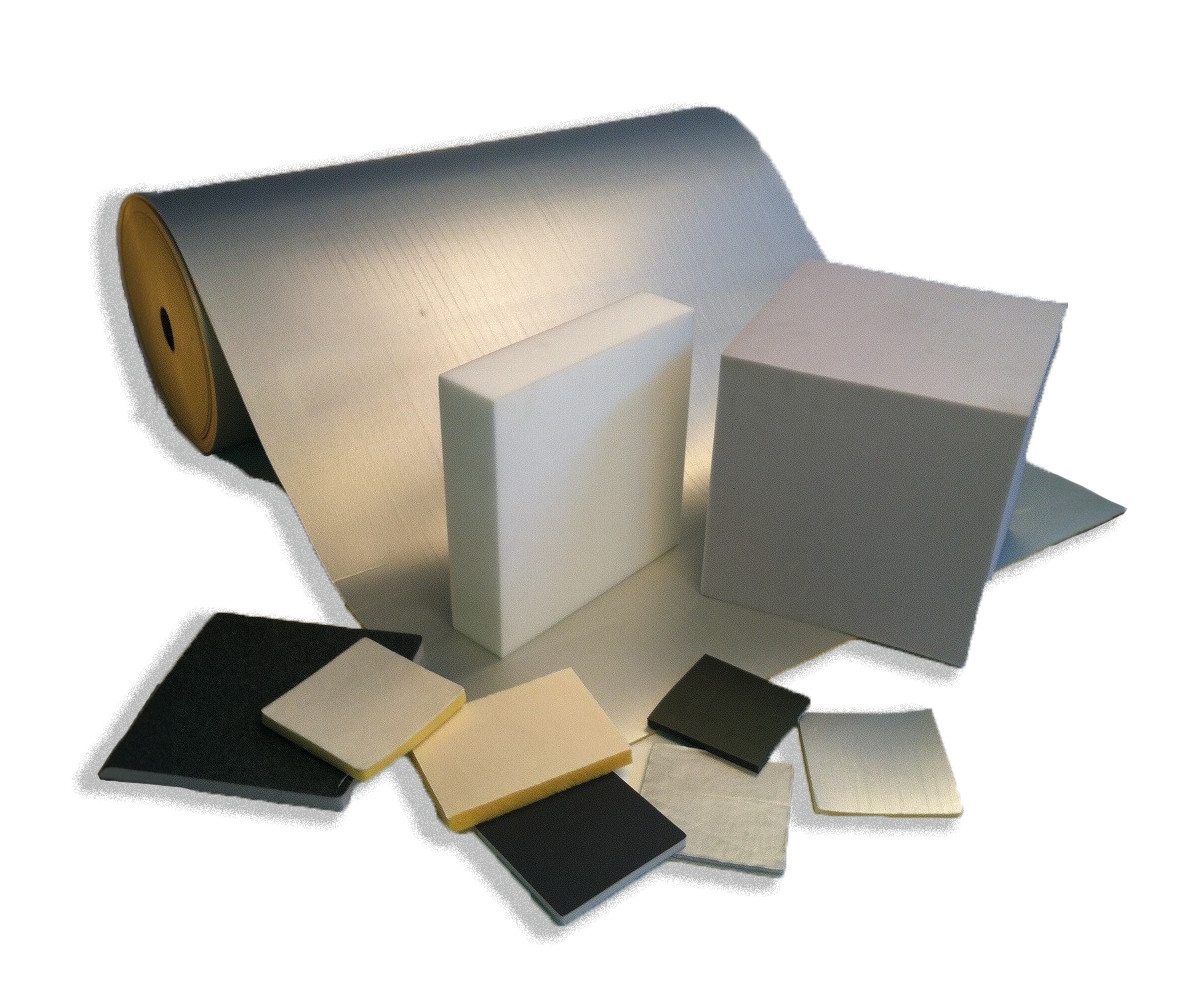

Soundcoat develops its solutions utilising a fully equipped acoustics lab; a materials testing lab; best-in-class predictive analysis and computer modelling tools; and two manufacturing facilities monitored under a rigorous system of internal quality control. With highly developed in-house competencies, it can deliver a variety of acoustic solutions including laminated composites consisting of films, acoustic fabrics or embossed facings; materials cut to shape with or without adhesive backing; or products in sheets, rolls or packaged in kits.

The company has a strict quality assurance policy and is ISO 9001:2015 registered at both its New York and California facilities. The California facility also carries additional AS9100 certification to handle the needs of its aerospace and aviation customers.